Seperated Drilling Machine YD345

33 Items in Stock

YD345 is suitable for rock excavation, original landscape investigation, small-scale mining application, blasting hole application of various hard rock types, foundation anchoring, casing and large-hole spiral drilling. Lightweight and flexi

| YD345 Technical Parameters | |||

| Diesel Engine Manufacturer | Cummins | Engine Model | 4BTAA3.9-C80 |

| Engine Rated Power | 60KW | Engine Emission | Euro II |

| F.A.D | 10 m3/min | Working Pressure | 7-25 Bar |

| Rotation Speed | 0-100 rpm | Rotary Torque | 2088 N.m |

| Hole Diameter Range | Ø90-140 mm | DTH Hammer | 3.5/4 inch |

| Hole Depth | 20 m | Number of Pipes | 6+1 |

| Drill pipe type | Ø 76 mm | Pipe Length | 3,000 mm |

| Feed Type | Cylinder / Chain | Length of Feed Beam | 5,430 mm |

| Feed Extension | 1200 mm | Feed Travel Length | 3,200 mm |

| Feed Speed | 1.1 m/s | Pull Up Force(Max.) | 35 kN |

| Max. Climbing Ability | 25° | Feed Force(Max.) | 18 kN |

| Tramming Speed | high 3 km/h | Traction Force( Max.) | 45 kN |

| Ground Clearance | 430mm | Fuel Tank Capacity | 60L |

| Length | 5,940mm | Width | 2,150mm |

| Height | 2,420mm | Weight(options excluded) | 5,500kg |

Main benefits:

Leading innovation, demonstrating today's most advanced manufacturing technologies.

High efficiency, energy saving, environmental protection and safety.

The separated DTH drilling rig is upgraded from the existing mature models and the core components are upgraded to the world famous brand.

Reliable performance, continuous operation in all weather conditions.

Features:

1. Powerful rotation unitA larger and stronger twin-cable drive rotary device is designed, which can output large torque, smooth speed regulation without gap, reduce the interference to drilling tools, and meet the requirements of basic anchoring, casing and large-hole auger.

2. Ergonomic comfortable operation console

Centralized control, convenience, efficient control console and full display panel of functions.

3. High efficiency dust collecting system

Own dust collector with high speed fan for larger filtration area, technical advanced and industry leading.

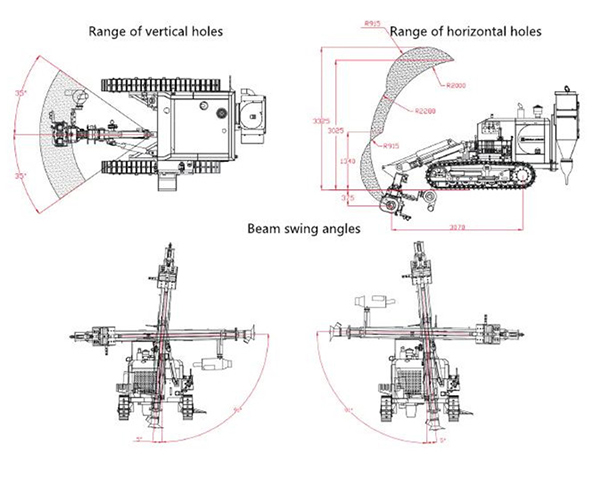

4. Multi-directional drilling design

For complex drilling conditions, 400 mm ground clearance for horizontal drilling applications.

5.Stronger Heavy Duty Feed Beam

Excellent for anti shear / cut, torsion and bending resistant to ensure precision drilling.

6. Three stage Air Filtration system

High performance wet air filter working with dry filters for three stage filtration system to provide complete protections for the engine.

7. Wear resistant slide padding

Wear resistant nylon made rotation unit padding and feed beam slide protective padding for less frictions and for rotary head smooth feeding up and down.

8. New protective cover

Better appearance and convenient for maintenance.

9. Standard tramming mechanism

Equipped with speed reduction tramming system and standard excavator track for compact structure. Excellent off-road performance with powerful two-speed hydraulic tramming system for extreme low failure rate.